Converting waste for a cleaner tomorrow.

YOUR PROJECT. OUR EXPERTISE.

Put our 30+ years of global experience and expertise to work.

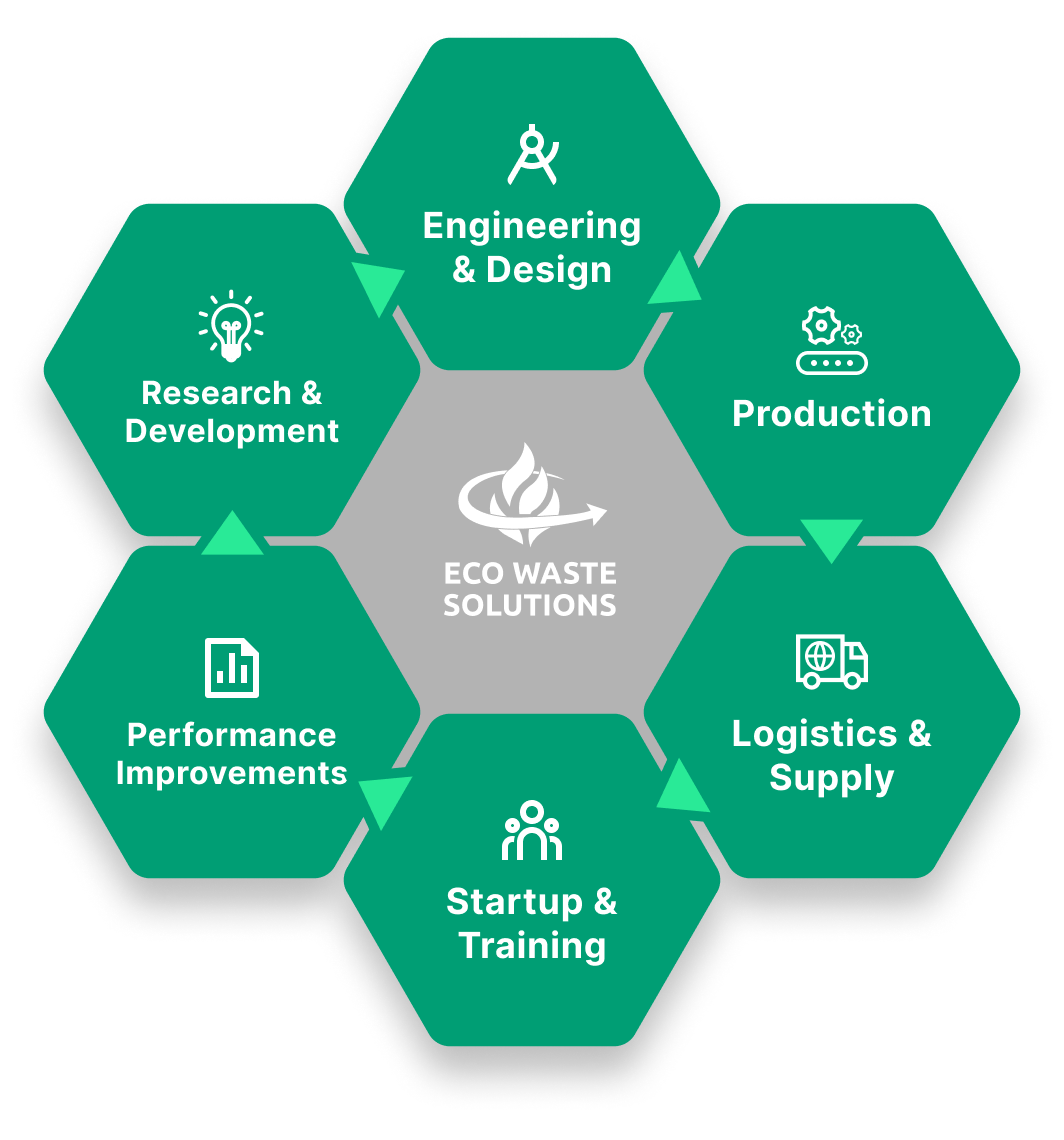

Our field-tested, proven consulting and support ensures success through every stage of your waste management project.

Engineering & Design

Technology

- Solid waste conversion technology design review and recommendation

- Air Pollution Control (APC) specification and selection

- Continuous Emissions Monitoring System (CEMS) specification and selection

- Energy recovery specification and selection

- Upfront engineering/costing/economic analysis

- Engineering specifications, designs and IP for modular mass burn, two-stage incineration, mobile, truck-mounted, containerized, shipboard, rotary, pyrolysis,

gasification

Environment

- Environmental regulatory permitting

- Analyses: Expected stack emission, effluent or residuals

- GHG (Greenhouse Gas) reporting, emission rates and modeling

- Air emissions test planning and support

Engineering

- Waste convertor design, upgrades or modifications

- Calculations, thermal release analysis, capacity requirement

- Process flow calculations and diagrams

- Integration: Energy recovery, air pollution control, emission monitoring, material handling, weigh scales, waste oil burners, etc.

- 3D SolidWorks modeling and 2D drafting: Site plans, plant layouts, machinery layouts, guarding and platforms, welding and fabrication drawings

- Electrical design: Electrical and controls modernization, process and instrumentation, schematics

Waste

- Waste analysis, waste management reviews

- Waste characterization for project scoping, permit application, feedstock guarantee or design-build

- Impact-benefit analysis for taking in new waste streams or additional waste to address new markets

- Analysis of plant capacity/burn rate for different feedstocks

- Waste heat value content (calorimeter) analysis

- Combustion calculations

- Capacity requirement confirmation

Production

- Quality management

- Vendor selection

- Procurement

- Custom fabrication

- QC/QA

Logistics & Supply

- Provision of complete parts and services logistics program

- Spare parts provisioning and recommendations

- Re-supply management

- Obsolescence management

Startup & Training

- On-site oversight of general contractors and trades

- Pre-startup checks and setup

- System run-checks, shakedown and optimization

- Performance testing and evaluation

- Operations and maintenance training

Performance Improvement

- Efficiency assessments, from collection to disposal

- Equipment inspection with report & recommendations

- Review of on-site specific requirements

- Review of operational logs, emission reports and maintenance records

- Design improvements, repairs and retrofit

- Waste heat value content (calorimeter) analysis

- Updated documentation and Standard Operating Procedures (SOPs):

- Operational SOPs

- Updated operator manuals and training materials

- Maintenance & preventative maintenance schedules

- Health & safety programs

Research & Development

- Technology investigation

- Conceptual and upfront engineering

- Design, prototype production, testing and evaluation

- R&D reporting